Why do you eliminate dust in receiving pits?

To protect both your workers and the environment

Mechanical DustControl

Automatic system to control dust in receiving pits

Main advantages of the system:

- Completely automatic

- No electricity required

- No maintenance needed

- Indefinite lifetime – first systems installed in 2003 are still working

- Passed 100% of environmental inspections in Brazil

- Custom-made for each pit

- Completely below grate

- Pneumatic clean-out option when products shouldn’t be mixed

- Reduction in “shrink” (weight of dust expelled into the atmosphere)

How it works

To enhance your DustControl in pits receiving excessive dust

DustControl Plus

The Mechanical DustControl + a low energy-consuming filter

• All the benefits of the Mechanical DustControl - completely automatic, no electricity required, no maintenance needed, indefinite lifetime, passed 100% inspections, totally below grate, optional pneumatic clean-out when products shouldn’t be mixed, reduces shrink.

• Added filter removes dust separating from the product above the pit by creating a negative pressure below the pit

• Reduces risks of explosion

• Substitute large inefficiente baghouse filters with smaller filters (can be preexisting filter)

DUST REMOVAL IN RECEIVING FACILITIES DECREASES RISKS OF EXPLOSIONS

200+ systems installed in Brazil and 50+ systems installed in the USA

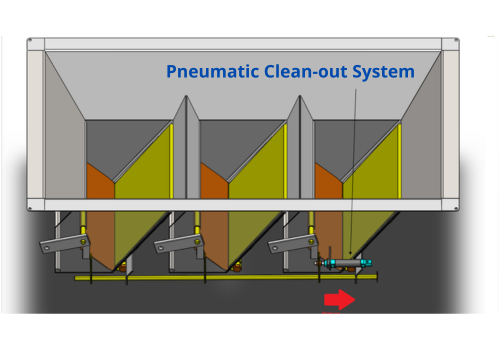

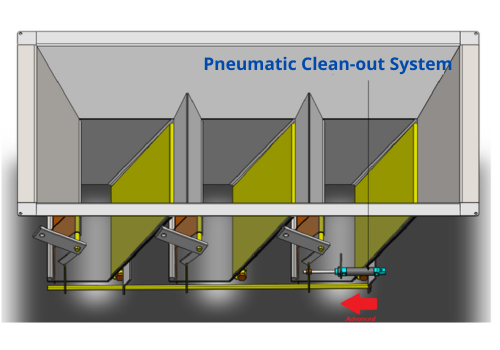

DustControl Pneumatic Clean-Out

O Sistema de Limpeza Pneumático do DustControl evita a mistura de tipos diferentes de grãos. Na troca de produtos, quando é necessário que as bicas estejam totalmente sem o produto antigo, o operário pode usar um bastão de vassoura para abrir manualmente as tampas e limpar as bicas. Para os casos em que se deseja uma limpeza rápida das bicas depois de cada descarga para não misturar os produtos, a Wings oferece um sistema de limpeza pneumático. Uma caixa de controle é instalada em um ponto perto do operário, com linhas de ar conectadas aos cilindros de ar em cada módulo. Barras de acionamento nas bicas abrem e fecham as tampas quando o operário pressiona o botão da caixa de controle. This system needs a small air compressor.

At the end of unloading, when the quantity of product is not sufficient to maintain the louver open, this small amount of product remains in the module.

When the button on the control box is pushed, the air cylinder opens the louver to empty the module chute. The pneumatic clean-out system is ideal for pits that receive different types of products that should not be mixed, as is often the case in feed mills.

For use in pits receiving: soybeans, corn, wheat, sugar, fertilizers, coffee and other bulk products

Pits and hoppers that receive bulk products have serious problems with dust emission, threatening the health of employees circulating in the area, creating conflicts with neighbors who are upset with dust in the air and just general pollution of the environment. All of these factors can lead to problems with local regulations and EPA inspectors that consequently lead to fines and legal costs.

There is an easy and effective solution for controlling dust emissions in receiving pits and hoppers. Mechanical DustControl baffles are metallic modules installed below the pit grate that utilize the product itself to filter the dust as it is being expelled from the pit.

The DustControl modules are only 15 to 20 inches deep (40-50 cm) with ducts that control the flow of the product into the pit, slightly slowing its velocity in order to maintain the ducts full of product. As the product is being unloaded, the modules first fill with product so that the dust-laden air being forced from the pit must pass through it. The product slows the velocity of the exiting air to the point that it can no longer carry the dust and it deposits the dust with the product. Essentially, the product is the dust filter.

A second advantage is that the air leaving the pit at a reduced velocity does not create an airstream that captures the dust above the pit and disperses it through the atmosphere, but by being slowed down, allows the dust generated above the grate to settle into the pit. The DustControl baffles keep the dust with the product which reduces shrink, the weight loss that occurs when dust is separated from the product during transportation. One of our port facility clients calculated that this savings in shrink paid for the DustControl systems within a year. If desired, modules can be manually cleaned between unloading. For feed mills that cannot mix their products and have frequent product changes, Wings offers a pneumatic clean-out system that facilitates this process. The DustControl is completely automatic without operators, and also maintenance-free. The first Mechanical DustControl systems, installed in 2003, are still working today without maintenance. DustControl works with almost all flowable bulk products including corn, soy, sugar, rice and fertilizers.

EXCELENTETrustindex verifica se a fonte original da avaliação é Google. Finalmente um equipamento que não depende de manutenção constantePublicado emTrustindex verifica se a fonte original da avaliação é Google. Adorei. Muito competentes e profissionais. Eu recomendo.Publicado emTrustindex verifica se a fonte original da avaliação é Google. A Wings tem o ESG no seu DNAPublicado emTrustindex verifica se a fonte original da avaliação é Google. Profissionais dedicados e com GRANDE experiência.Publicado emTrustindex verifica se a fonte original da avaliação é Google. Empresa incrivelmente comprometida com a qualidade de seus produtos e com atender bem o cliente. Sou testemunha.