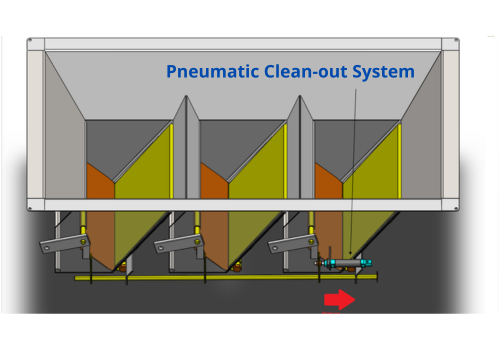

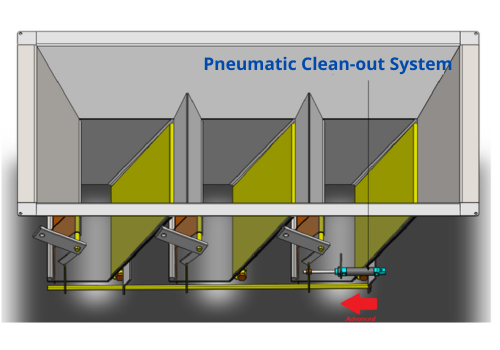

The DustControl Pneumatic Clean-out System is used to avoid mixing different types of grains during the unloading process. The DustControl is composed of metal modules with chutes and counter-weighted louvers that controls dust emission from receiving pits. As grain is unloaded into the hopper, it falls into the module chute and the weight of the product forces open the louver. At the end of unloading, the louver on each module closes and a small amount of grain remains in the chute.

If it’s important that the chutes be completely free of product during a changeover, an employee can use a broom stick to manually open each louver to empty the chute.

If you want to speed up the process, the Wings Pneumatic Clean-out System can be installed. A control box is mounted at a convenient location near the pit and air lines are connected to air cylinders mounted on each module. These cylinders are attached to drive bars that open and close the louvers when the operator pushes the button on the control box.

This system needs a small air compressor.

At the end of unloading, when the quantity of product is not sufficient to maintain the louver open, this small amount of product remains in the module.

When the button on the control box is pushed, the air cylinder opens the louver to empty the module chute. The pneumatic clean-out system is ideal for pits that receive different types of products that should not be mixed, as is often the case in feed mills.

More than 250 projects installed in the US and Brazil

.